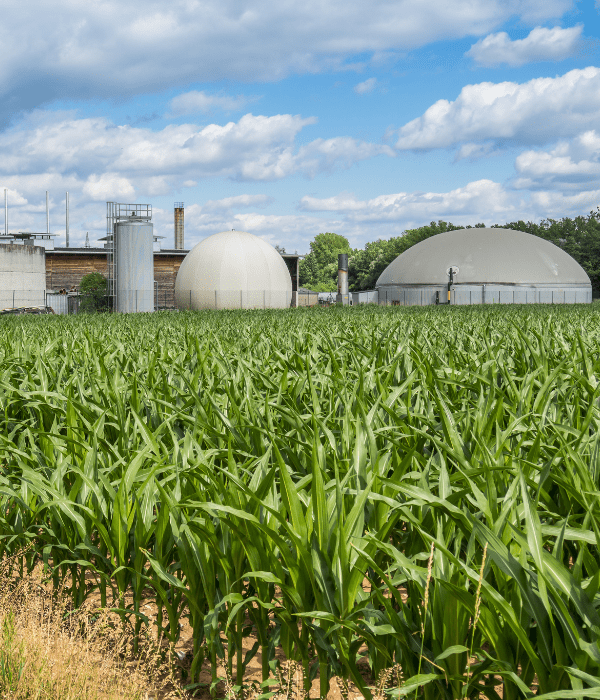

Biogas production by anaerobic digestion – how can it be optimised?

Ensuring your anaerobic digestion plant is producing the optimum and, indeed, maximum amount of biogas achievable is of course a priority for all AD plant owners and operators around the country; providing you with the best possible outcome, whether you use your anaerobic digestion plant to provide an additional income, as a waste management solution or simply to support heat & power production on your farm. So, to help you get the most out of your AD plant, we’ll explore an answer to the question: how can biogas production by anaerobic digestion be optimised?

How can biogas production by anaerobic digestion be optimised?

Balance pH levels: balancing and maintaining the pH levels of your anaerobic digester is key to biogas optimisation and yield. This is because the microorganisms utilised during the process of anaerobic digestion are all extremely sensitive to pH and all live healthily at different levels.

Monitor & control temperature: last month, we discussed the difference between thermophilic and mesophilic anaerobic digestion – mesophilic being the most common type of AD in the UK, where thermophilic refers to higher temperatures and mesophilic refers to slightly cooler temperatures. But, within and alongside this is the fact that the microorganisms used during the AD process are sensitive to temperature and, as such, carefully monitoring and controlling the temperature of your AD plant will be crucial to optimising biogas yield. However, its important to note that decisions to change the temperature range of your AD plant should be agreed with the AD plant process designer.

Organic Loading Rate (OLR): the Organic Loading Rate (OLR) refers to the volume of solids added to the digester per day. This rate is used by the Plant Operator to decide on the mass of feedstock to be added to a digester each day, depending on the volume or size of the digester and to yield the optimum biogas output.

Nutrients: nutrients can play a pivotal role in the optimisation of biogas production in anaerobic digestion where microorganisms require very small quantities of ‘micronutrients’ for their growth. The presence of micronutrients can be crucial to maintaining a stable population within the microorganisms which perform anaerobic digestion.

In conclusion, there are a handful of, fairly simple and accessible ways you can optimise biogas production by anaerobic digestion: balancing the pH levels, monitoring the temperature of your digesters, optimising the OLR and ensuring the microorganisms used during the anaerobic digestion process receive the correct micronutrients in order to optimise their performance.

Find out more about our anaerobic digestion plant construction services or contact us to discuss your project.